As the most fundamental and basic industry of the national economy, the power industry is involved with the security of national economy and the stability of society. The failure of power system can cause great impact, but can hardly be detected by common methods in the early stage.

With the advantages of high precision, high efficiency and overall detection of fault point, the handheld thermal imaging cameras not only have solved the difficult problems of fault detection & prevention, but also become the key detection equipment in the industry after coming into the market.

So how to choose the most suitable lens for the handheld thermal imaging camera? Continuing the theme of "Thermal Imaging Lens Selection Guide" series, this article will share the idea of selecting and purchasing the infrared lenses for handheld thermal imaging camera.

Step 1: select the appropriate standard lens

The FOV of the IR lens for handheld thermal imaging camera is relatively constant, usually 24°, 32° etc. And the focusing mode can be divided into 2 types, one is core focusing, the other is lens focusing.

In the first mode, the lens under focusing is statically while the core is driven to move by an electric mechanism. So in this mode the lens can be replaced easily, also has access to more functions like built-in shutter, manual & automatic integration.

In the second mode, the focusing is realized by the movement of lens elements, manually or electrically. This mode is more user-friendly as there is no movement of core.

Step 2: select the appropriate magnification lens

The standard lens may not meet the requirements in some special cases like measuring the temperature of a huge target closely, or a small target in a long distance. As a result, we need add a magnification lens, whose common specifications are 0.5X (for short distance & wide FOV), 2X/3X (for ultra-long distance).

The magnification lens can be divided into exchangeable lens and extended lens based on the installation.

For the exchangeable lens, it can been seen as standard lens with different focal length. The advantage of exchangeable lens is space-saving and cost-competitive. But the lens exchange process might not be easy and during the exchange, the risk that particles get into the camera will increase greatly.

For the usage of extended lens, you only need to assemble it on the standard lens, thus making it easier for switching and protecting the core from particles. However it is not competitive in space and cost, normally only suitable under dusty and other harsh environments.

Step 3: add more configuration options for special applications

There are plenty of scenarios for the applications of temperature measurement. So for some special applications, you will need additional configurations selection. For example, when in a scenario with a wide temperature range (like -40~1200℃), with single-aperture lens, the thermal imaging camera with big aperture lens will face the risk of over-energy and damage on the core at high temperature; and camera with small aperture lens might have a poor measurement accuracy at low temperature. In this case, we will usually add a shutter inside the lens, which means, add multi gears of shutters (generally 3 gears: full-open, half-open and full-closed) to meet the requirement of temperature measurement under different environmental temperatures. In addition, a shutter correction inside the lens will help improve the accuracy and stability of temperature measurement.

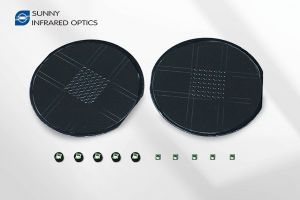

Sunny Infrared Optics is the world’s first enterprise who offers the one-stop production service from chalcogenide glass smelting to infrared lens assembly. With the core of leading optical technology, and the innovation as impetus, Sunny Infrared Optics commit ourselves to providing high-quality thermal imaging lens solutions and service to the global customers, meeting their various standards and customized requirements. Please feel free to contact us if you have any question or requirement.

+86 574 6253 0985

No. 360, 362 Fengyue Road, Yangming Street, Yuyao, Zhejiang Province, China

Copyright © Ningbo Sunny Infrared Technologies Co., Ltd. (Subsidiary of Sunny Group) | Sitemap | Technical Support: