As a common optical component, also known as the protective window, infrared windows usually installed at the front of thermal imaging lenses, mainly used for lens protection, enhancing the lens resistance to external environmental erosion and impact resistance. The main material include germanium, silicon, zinc selenide, barium fluoride, calcium fluoride, etc.

So how do we choose the appropriate infrared windows according to the different application environments?

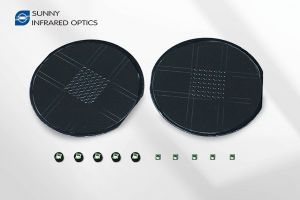

For indoor applications, such as the thermography products, the anti-reflective coating applies on the both window surfaces. In addition, the window materials include barium fluoride, calcium fluoride, etc.

For outdoor applications, germanium and silicon materials are priority choices. Diamond Liked Carbon coating applies on the outer surface of window to adapt to harsh environments. In extreme environments, such as nearby sea, which is very salty, and moisty, the germanium window is need to ensure a better operation and easy replacement.

For strong impact resistance applications, Silicon and germanium window with DLC coating are first choices. For example, in automotive night vision, silicon window can better avoid the resistance impact from stone chips.

Reliability tests are an important part of evaluating the performance of infrared windows, and it is the key to ensuring the stable operation of windows in actual usage environments. Sunny Infrared Optics is equipped with a series of reliability testing equipment, including high and low temperature test, salt spray test, abrasion, etc., as well as special performance testing instruments such as three comprehensive vibration tables(Temperature& Humidity& Vibration), mechanical impact tables, stone chip equipment, sand blowers, etc.

+86 574 6253 0985

No. 360, 362 Fengyue Road, Yangming Street, Yuyao, Zhejiang Province, China

Copyright © Ningbo Sunny Infrared Technologies Co., Ltd. (Subsidiary of Sunny Group) | Sitemap | Technical Support: