As an important factor determining the performance of thermal imaging lenses, infrared materials typically include chalcogenide glass, germanium, ZnS, ZnSe, Si etc. Chalcogenide glass is becoming the most popular material due to wide transmission range, low temperature coefficient of refractive index, and high cost-effectiveness.

Recently the export restrictions and the increasing price of germanium impacts the supply chain of the infrared lens. Chalcogenide glass is the best alternative material to germanium with the improvement of performance and processing methods. There are three advantages as below.

Stable supply

Germanium is a scarce material due to its limited reserve and high mining cost. In addition, the recent export restrictions also impacts the stability of its supply.

While chalcogenide glass does not have the above limitations and we have sufficient production capacity.

Diversified processing methods

Processing method of germanium typically includes polishing and turning due to its high melting point.

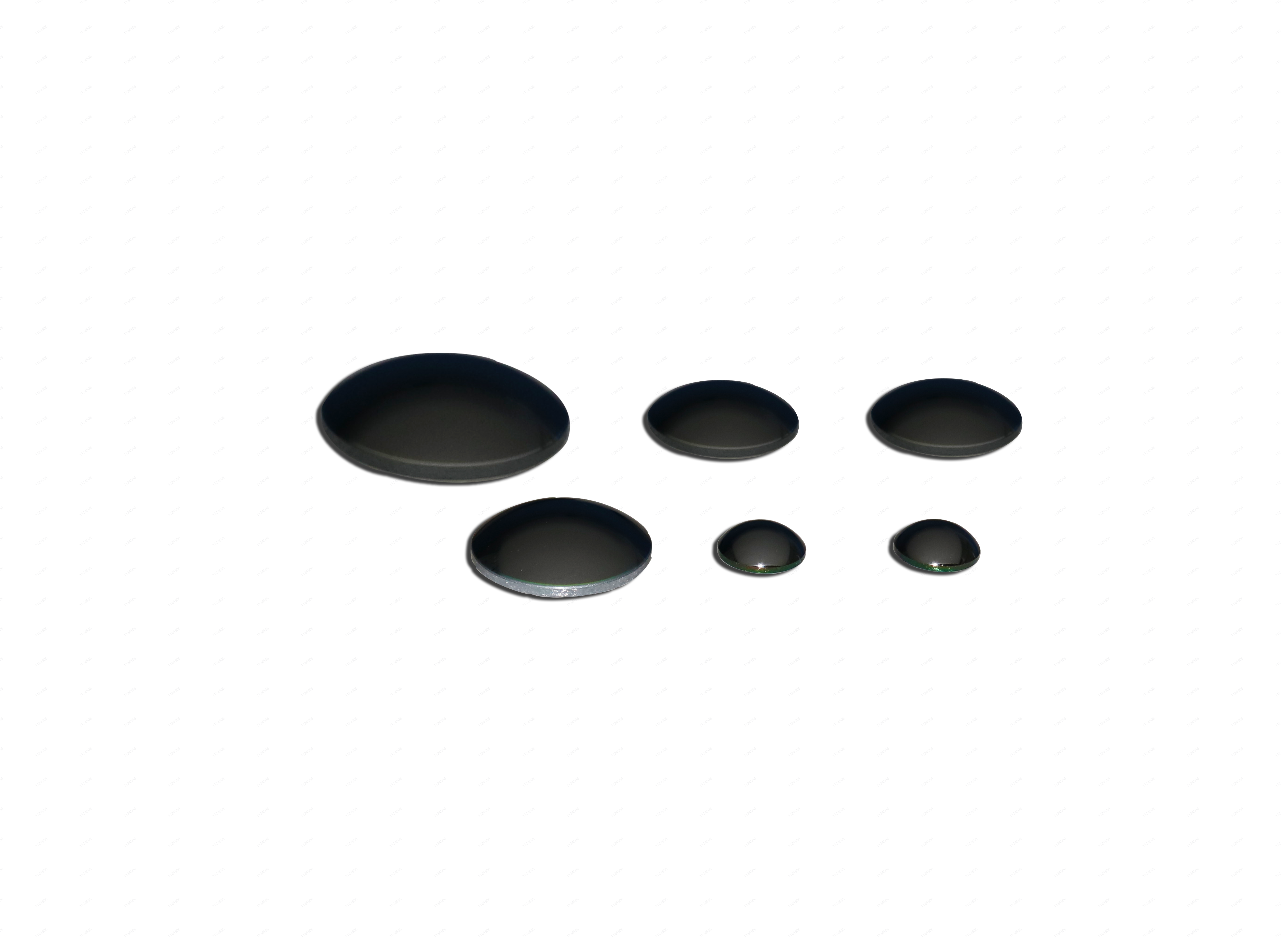

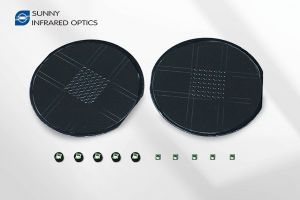

Chalcogenide glass is an amorphous material with a low softening temperature. In that case, it is not only suitable for polishing and diamond turning, but also for molding which could bring higher efficiency and more cost advantages.

Excellent optical performance

Chalcogenide glass has a wider wavelength transmission range covering three atmospheric windows of 1-3 μm, 3-5 μm, and 8-12 μm. It has 8 times lower change of refractive index with temperature than germanium.

Sunny Infrared Optics has been dedicated to the development of chalcogenide glass material, processing technology, and chalcogenide glass lens since its establishment.

Chalcogenide glass is not only the preferred material for athermalized lens, but also suitable for big lens with manual focus, motorized focus, or zoom.

Manual focus and motorized focus lenses are mainly for observation and monitor. The lens usually consists of 2 or 3 pieces of chalcogenide glass. It has the same optical performance but lower cost compared with germanium lenses of the same diameter.

Zoom lens is mainly for forest firefighting and vessel detection. The lens usually consists of 1 or 2 pieces of chalcogenide glass. Using chalcogenide glass for first element design could further reduce the cost.

Furthermore, chalcogenide glass-based SDLC is already successfully developed for complex environments. It could meet severe abrasion and has better transmittance than DLC coatings.

As a leading global one-stop provider for infrared thermal imaging lenses, Sunny Infrared Optics has mature processing capabilities for chalcogenide materials, grinding, molding, turning, and assembling. If you have further requirements for thermal lens solutions, feel free to contact us anytime.

+86 574 6253 0985

No. 360, 362 Fengyue Road, Yangming Street, Yuyao, Zhejiang Province, China

Copyright © Ningbo Sunny Infrared Technologies Co., Ltd. (Subsidiary of Sunny Group) | Sitemap | Technical Support: